Over the years, I have been lucky enough to see and handle literally thousands of chairs. I have bought chairs and developed chairs in factories all over the world, and after a while, it becomes an all-consuming obsession. Before I get on to Baumann, there are a few things I need to explain about chairs.

Firstly, like a cotton shirt or a ceramic plate chairs have been around for a very, very, long time, I’m not sure we know who produced the first one, but perhaps it was simply a favourite rock or tree stump, the fact is weary legs drove the creative minds to come up with somewhere to rest. The second aspect stems from the first, since time in memoriam designers, producers and users have been designing and developing different chairs. It astounds me how for such a simple piece of practical furniture, the world can keep coming up with different designs for what is essentially somewhere to rest.

The design of chairs has of course been driven by the designs and fashions of the day and each design period has had its own very recognisable shape, whether that be the Chippendale chair of the 18th Century or the balloon back chair of the Victorians. And lastly, again related to all the above, the advance of chair design has usually been fuelled by the discovery of a new material or production process. The Bauhaus were the first to really exploit tubular metal in chair production, Eames applied the new material plywood and then fiberglass and so on.

And the last intriguing fact is that a good chair is often produced in vast volumes, think about it, every bottom needs a chair but say a group sits around a table (Oooh, think hotels, conferences, schools and the cash register starts ringing) then by ratio you always need more chairs to tables. So, a commercial designer is driven by the greed of unending chair royalties and the ‘fame’ that comes with a successful new design.

The long and the short of it is simply that every designer worth his or her salt wants to create a famous chair, it is the pinnacle of success both egotistically and financially to nail that successful chair design and have it produced in volume. Chairs have by default pretty much-driven furniture design since furniture design mattered. So, I guess that’s why I am a bit obsessed with vintage seating, they are a very good marker for the various fashions in furniture design and tend to represent the major milestones along the way. Don’t worry; we are getting closer to the Baumann story.

- DOVE

- MONDOR

- SPINDLEBACK

- GENTIANNE

- CLASSIC

- BISTRO

- CAFE

- MOUETTE

The Origins of Steam Bending

One of the major chair milestones was the industrialisation of the manufacturing process made by Thonet in the 19th Century. As the industrial revolution boomed, the demand for well-priced industrially produced furniture skyrocketed.

The first person to spot that opportunity was Michael Thonet when in the 1850’s he pioneered the process for steam bending beech, which ultimately made chairs both easier and more economical to produce but also allowed unseen before creativity in chair design. Thonet and his bentwood process facilitated the creation of arguably the most famous chair of all time chair, Number 14 – better known as the coffee shop chair. It is said that over fifty million of these chairs have been produced to date, and it is to this day still very successfully produced in large volumes.

The steam bending technique allowed for the industrial production of a chair for the first time ever. The second milestone of the chair was the fact that it could be disassembled into a few components allowing economies of scale in production akin to the capitalist observations of economist Adam Smith. The chair could thus also be exported globally in smaller economic packaging.

In the nineties, I had the privilege of going to an original Thonet factory in Czech and was captivated by the process, long lengths of thick beech perhaps 4cm by 5cm were super-heated in pressurised steam chambers. When they were ready, they were pulled out and ‘bent’ by the biggest and strongest workers you can imagine, around steel moulds to ‘form’ the various components of a bentwood chair. I could not believe it at first, these are thick heavy bits of timber almost as floppy as spaghetti after a few hours in a steam chamber. Next time you sit on a bentwood chair look at the seat section, the ring that circles the ply seat is bent from a single piece of beech, into a circle thirty centimetres diameter.

I labour this story because it was in itself the single most important driver of chair design for the following sixty or seventy years. Thonet was so successful that he required factories throughout Europe, often in Eastern Europe where Beech was readily available, and he set up a vast network of shops selling and distributing his chairs throughout the world. It was an empire, built on the simple invention of steam bending.

And this is where Baumann was born. When some of the Thonet patents expired, the market was swamped with competitive upstart’s keen to take a slice of the pie created by Thonet. Thonet had many competitors, amongst others, Fischel, Ton, Luterma and of course Baumann. Baumann was founded in 1901, by Swiss man Emile Baumann, in Colombier Fontaine, France. Baumann started producing a simple child’s chair ‘charette’ but grew rapidly to be a large bentwood producer cleverly marketing its brand as ‘the chairs of France’.

In time, Baumann had showrooms all over France, in Paris, Lyon, Marseille, Bordeaux, Lille, Nantes, but also in Algiers, Oran and Tunis. At its peak in the ’70s, it was producing nearly one million chairs a year. It was also well known as a family business with Emile’s sons Walter and Max working in the firm as it grew exponentially in the years after the war.

What Made Baumann So Successful?

In my view, there are several notable points that fuelled Baumann’s success.

Firstly, they produced some superb classic Bentwood chairs in the manner of Thonet; they were a large producer and supply for the almost endless demand from French cafes and restaurants for what was almost the ubiquitous chair of this period. Batches of these beautiful chairs still come up, often from restaurants where they have been used for years, yet they are still in immaculate condition.

One of the strengths of these chairs is they were very well designed for contract use, and the slight give in the underframe supports meant that rather than glue joint breaking over the years they had a little bit of inbuilt flexibility and if they did develop a bit of a wobble the chairs could be simply tightened up with a few basic tools. Literally hundreds of models existed, and alongside competition from Thonet, Fischel and Luterma (to name a few) these classic Baumann chairs invaded French culture from for most of the first half of the 20th Century.

At the same time, Baumann developed and sold a range of café dining tables, and the ones we love and seek out are the cast base versions from the twenties and thirties. The cast metal bases are heavy and beautifully made, and the classic Baumann shape is a swooping bell-shaped curved leg. Hard to find these days but worth hunting out.

And lastly, we get to what perhaps our article is all about, the golden period of Baumann in the late fifties and sixties. After the war, as the dust settled and a new modernist style emerged from Scandinavia, Baumann launched a series of absolutely stunning mid-century chairs, Scandinavian Mid Century in spirit but a classic French twist and a grace that few chair producers have matched to this day.

What Made Baumann Chairs The Understated Mid Century Icon?

The chairs were based around two basic constructions. The first was a simple round seat with slim tapered and protruding legs various back options. The most beautiful models from this period are the Mondor and the Dove. And the second was using laminated wood to create a curved seat and a curved back; this was by far the most successful for Baumann with many models using this construction, Fourmi, Mouette, Gentianne to name a few.

![]()

The laminated timber construction was not new, it was pioneered by Aalvar Allto for Artek and also used in England by Isokon. To produce the required shape, a male mould was created and then on to this several thicker layers of veneer (approximately 1.2mm) were layered, each layer being generously glued. Whilst still wet and flexible the ‘pile’ of veneers would be then pressed under vacuum pressure or press weight into (or onto) the mould and left to dry in that shape. When the glue dries, the veneers retain the moulded shape, and the shaped panels are then trimmed and finished and used in the chairs. Basically, the same construction as layered plywood but laid on a shaped, not flat, mould.

In this series of designs, Baumann used a formed laminated seat and back as a construction with subtle differences in design. The chairs were incredibly strong with the backs being beautifully bolt fixed to the bases (which also allowed them to be tightened as needed) and gracefully tapered legs fitted into strong subframes. I have been lucky to see hundreds of these chairs now, and the vast majority are in excellent structural shape despite often having served over fifty years’ service in restaurants or cafes.

In my view, these mid-century laminated chairs by Baumann are massively underrated, and I am not the only one to think that as demand has steadily risen and they are becoming increasingly hard to find. They are a beautiful design, well-proportioned and amazingly comfortable, beautifully made and made to last. I would stake a claim that they are one of the best mid-century chairs out there. Although they were principally designed for cafes and restaurants, they look amazing in a private setting and give a much more subtle twist to a classic mid-century dining setting than a stiff ‘matched’ table and chair combination. Don’t get me wrong, I love a bit of Scandinavian teak, but it can have a slightly linear and precise look, and as it was often designed in ‘sets’ it can be a bit showroom matchy-matchy but mix in some Baumann chairs, and you add a different dimension, a more organic form and a more relaxed feel.

Baumann’s Heyday – 60’s and Beyond

In the sixties and seventies Baumann flourished, producing close to a million chairs a year, they exhibited at all the major furniture design fairs and continued to develop new innovative designs through the seventies and eighties. Sadly, the curtains closed on Baumann in 2003, perhaps a combination of import competition from Asia which saw huge swathes of production moved East and simply perhaps because they failed to keep pace with the rapid evolution of product trends.

Baumann is definitely one of our favourite iconic makers, and we will continue to dig into its history and share what we find. We recently bought an original 1930’s catalogue and would love to find one from the fifties if anyone reading this can help. We try to keep a decent stock of Baumann chairs and tables and love the fact that we give them a gentle clean and tighten the joints before finding new homes for these beautiful chairs.

They are getting harder to find as most of our sourcing comes from restaurants and cafes and batches of forty or so chairs are drying up. My advice is snap them up whilst you can and hang on to them, they will undoubtedly appreciate over the coming years, and besides, you will know you are sitting on some of the most beautiful chairs ever produced.

Click here to see our current range of vintage Baumann chairs. You can also contact us on +44 (0) 1256 760 044 or email paul@merchantandfound.com.

- DOVE

- DOVE

- DOVE

- DOVE

- CAST

- CAST

- CAST

- CAST

- CAFE

- CAFE

- CAFE

- MOUETTE

- MOUETTE

- MOUETTE

- MOUETTE

If you have been following our journey at Merchant & Found, you will know we have always been big fans of the work of British designer James Leonard. What has surprised us is just quite how little is known about him, what he designed and his legacy. A quick Google will throw up very little with the only decent article being by Peter Wyeth for Mid Century Magazine. Curiosity got the better of us so we contacted the delightful Mid Century magazine editor Tabitha Teuma, who very kindly put us in touch with Peter. We dropped an email to Peter and was delighted to receive a charming reply and a subsequent telephone call was arranged.

A few days later Peter and I managed to catch up on the phone and he teased me with a few stories about the elusive Mr Leonard so I felt a lunch date to progress our conversation was the best option. I was basically hoping that free food and alcohol would allow me to ply as much as I could out of Peter. A week or so later we finally met for lunch and shared what we knew about JL. It turns out that Peter is a bit of an amateur sleuth and the only active member of the JL fanclub, although I think he realised that I was about to sign up as the second (at this stage honorary) member. To cut a long story short we both have a passion for design and architecture and are both great fans of the JL story. We have agreed to further our research and somehow do justice to a man whom we consider was not just a great designer but a very important part of the development of British furniture in the post war ‘modernist’ era. We haven’t quite put a plan together but we have agreed to further our research, to put a timeline together, possibly champion an exhibition? But most importantly to gather together as many facts as we can and celebrate the work of the elusive James Leonard.

So to start with, here is a very brief synopsis of some of the facts, mostly plagiarised from Peter’s article for Mid Century Magazine but with the addition of a few extra snippets along the way. We have evidence from the London picture archive that the Educational Supply Association had offices in a rather grand building on Grays Inn Road in 1879. From what we can gather it was essentially a business set up to supply schools with a range of equipment from desks, stacking school tables and other furniture through to books and equipment. It was undoubtedly started around the time that the law changed at the end of the 19th century to make school education compulsory and a whole new burgeoning market opened. We know ESA produced much of their range and had a factory in Stevenage which specialised in wood furniture production, we have an aerial photograph from 1928 (Courtesy of Britain from Above).

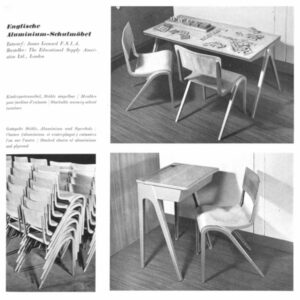

ESA was run by a larger than life character Jonny Appleton. In 1946 having just demobbed from the RAF and at the age of 42 James Leonard joins ESA as a designer and courts JA with his passion for modernist design and opens his eyes to the Scandinavian modernist design movement. The two of them head off on a whirl wind trip of the leading players of the time in Scandinavia, Artek etc and following JA’s design epiphany JL starts work on a new modernist collection for ESA. At this time there was much support for the use of new materials and ‘industrial production’ using some of the learnings from war production and JL champions the use of cast Aluminium and moulded plywood as key materials. One of JL’s first major designs for ESA was undoubtedly the X200 Aluminium nesting Chair, designed with a stunning refined aluminium frame that could only be produced by pressure casting of Aluminium and not sand casting, JA was at this stage hooked so at vast investment (£50,000) the right equipment was purchased in the US and JL’s aluminium framed chair was born.

The key period of design was 1947/1948, and proof of this exists with publication of the designs in Domus in 1948 and the British Design Annual, two years before the ‘innovative’ so called compass leg design of Prouve, that’s a whole other story…

We believe that over 1 million chairs were produced in a 15/20 year period and a whole range of aluminium and plywood furniture was developed for what must have been a very successful phase of ESA’s development. At some stage the brand name ‘Esavian’ was created, a mix of ESA and ‘Avian’, It was created as a brand to sell products within ESA and we have good evidence of JL products branded Esavian but at some stage ‘Esavian’ became a brand in itself and started to develop screens, initially for school partitions, which grew into sliding doors which grew into huge sliding/folding doors for aircraft hangers, the aircraft door opportunity really launching in 1971 when Nigel Jewers joined ESA with a considerable knowledge of the larger sliding door market and in 1987 Jewers acquired the Esavian door business from ESA. To this day Esavian doors is still part of the Jewson stable.

James Leonard appears to have worked at ESA until his retirement in 1982 and sadly ESA closed its doors on 11th February 1987. (Source DL Hanick JL’s assistant from 1951). So there you have it, a rather fast and sketchy history of ESA and James Leonard, but take this brief journal entry as just the start. Our mission is to pull together a far more comprehensive story, to fill in the blanks and champion the elusive Mr Leonard. If you have anything to add, or indeed want to join our rather small (but it has doubled in size) fan club then please let us know.

With thanks to Peter for his help and input, the story will continue.

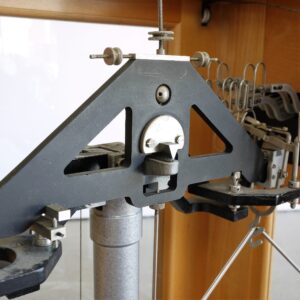

Traditional manual beam operated precision scales are sadly disappearing from daily use as electronic scales take over. Precision balance scales are commonly found in laboratories where they are kept in protected environments avoiding dust and any form of damage. Precision balance scales are simply used to maintain the accuracy of other scales, the precision scales being the ‘mother’ test standard. Each scale operates within a weight range so for example a scale 10g – 100g, 100g – 500g and so on, testing and maintaining the accuracy of the weights used on the other scales. The Precision balance scales have a master set of weights which are very carefully handled with gloves as use, damage, even the natural oils in the technicians fingers can alter the weight. The master weights are firstly used to check their own accuracy and then used to measure the accuracy of other weights used in daily operations in a laboratory environment.

This large collection of scales came from the VEF factory in Latvia. The VEF factory was founded in 1919 and produced a variety of electrical componentry and most famously the worlds smallest Minox camera. After WWII VEF grew substantially to be the largest factory in Latvia producing over two thirds of the telephones used in the Soviet Union.

The scales date from the 1950’s and are sold principally as decorative items. The larger scales have amazing cast metal assemblies and are thus quite heavy. Most of the scales work but they need to be set on a fairly level surface where they then need to be levelled precisely using the adjustable feet and various other internal levels. When perfectly level the beams can be balanced and adjusted and the scales will balance.

A stunning piece of practical history from the VEF factory.

A few weeks ago we heard about Crowle brickworks, a derelict brickworks outside Scunthorpe that was being demolished. The brickworks had been producing bricks since the late 19th Century although it sadly stopped production in the 1970’s.

Crowle Brickworks was established around 1880 by George Robinson (a local entrepreneur), adjacent to his brewery to the North of the railway and canal. As with any brickworks the value of the works rests in the availability of good local clay which Crowle had in abundance and it was brought to the works by a small tramway which was initially operated by horses. The works had a large brick kiln and were mechanised with power being provided by a fixed bed steam locomotive that ran a series of large pulley and web belts throughout the site.

In 1895 George Robinson was declared bankrupt, and it was not until 1906 that creditors of George Robinson sold both Tetley Hall and the Brickworks at auction and the works went on to a further chapter under new owners. At the time of the auction, the brickworks was described thus; The Crowle Brick and Tile Works, consisting of engine house, machinery shed, drying sheds, kilns and other buildings together with a boiler, 17 horse power engine, 2 newly erected brick making machines, belting, pulleys, hauling gear and other fixed plant and machinery, and also the valuable bed of clay used in connection with the works.

We were told that there was some pigeon holes on site, would we be interested? You have never seen us move so fast. Trucks packed up, boxes of all the right tools, gloves and dust masks. The yard was left untouched for over 50 years and the pigeon holes were housed in this very plain Victorian building which had sadly lost its original slate Victorian roof although it still retained the wonderful cast iron support structure. The shed was the ‘engineering shed’ primarily used to store mechanical components used to maintain the steam engine and steam tramway. The pigeon holes were stuffed full of rare steam engine parts that were scooped up by a collector. Our photos don’t do the find justice, there was over 60 metres of pure Victorian pigeon holes, untouched and in extraordinary original condition. On some planks of pine the original sawmill black dye stamps were clearly visible, the pigeon holes were made from the finest imported straight, knot free CANADIAN pine. George Robinson, a man of expensive taste.

A rare and exciting find.

We were recently contacted about the clearance of an old textile Mill, H.Green & Co, North West of Leeds, the Mill had stopped working as a textile mill many years ago and most recently was refurbishing electronic components. Housed in a wonderful Victorian brick building close to the River Aire the Mill was in Cononley West Yorkshire. In the 19th Century textile production was a huge industry in the region, enabled by good access to canals for transport and rivers for the water for textile production.

Apart from the building not much remained of the Victorian textile Mill history but hidden at the back of one of the workshops we found a very dusty collection of the original mill equipment, workbenches, storage boxes, trestles and trolleys. Heavy Victorian working equipment. Given their age (mid to late 19th Century) everything was in pretty good condition so we have simply given everything a gentle clean to bring out the original colour. The mill workbenches benches are the ‘piece de resistance’, weighing nearly 100kg, they have solid cast iron legs and heavily used original pine worktops. Perfect as the real deal console table or even as a rather heavy duty potting table. There was a number of gorgeous pine boxes, solidly made and with the standard wire reinforcement. The box maker, WM Bannister & Co Ltd Cowling Nr. Keighley (just a few miles down the canal) was clearly stamped alongside the Mills branding, totally original. The larger boxes were used for storage in the workshop and the smaller more rugged ones are heavy duty shipping containers for machine parts. We recovered one complete box which still has its original bolted lid, a heavy rugged box used for shipping. We got hold of two pairs of stunning large trestles most likely used for access platforms around the machinery and two great trolleys.

A wonderful find and a lost slice of North England’s rich manufacturing history.

Its hard to know where to start, this unique Fondation is one of the true gems in the world:

- The location is magical.

- The light is breathtaking.

- The building is sublime.

- The art is sublime.

- The history is moving.

- The atmosphere is beautifully intimate.

Saint – Paul de Vence is a bit touristy but still lovely. Have lunch (or stay) at the La Colombe d’Or and don’t forget Miro’s chapel nearby (Chapelle du Rosaire de Vence

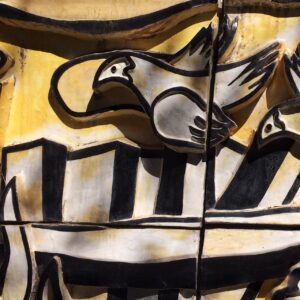

The Maeght family started when bought a property in Saint-Paul de Vence in the early 1950s and named it “Mas Bernard” after their son, who died in 1953 aged only 11. The early death of their son had a profound effect on the family and along with friends, Georges Braque, and other artists, Aimé and Marguerite Maeght created the Fondation. In 1964, Catalonian architect Josep Lluis Sert designed the building and along with the the artists Giacometti, Miro and Braque, they designed the gardens and art for the landscape. The family were responsible for printing many of the great artworks of the time and still operate the Maeght business which in itself is a treasure trove in central Paris, totally off the radar but chock full of extraordinary art, history, catalogue overruns… just amazing, and all for sale.

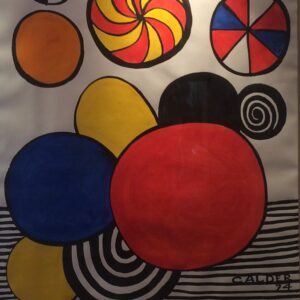

Works by Calder, Miro, Giacometti… and on and on….

They also host regular terrific exhibitions.

Go and enjoy a wonderful rare treasure.

Simple but tasteful letterpress cards and matches, link below.

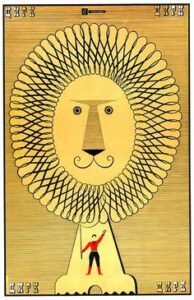

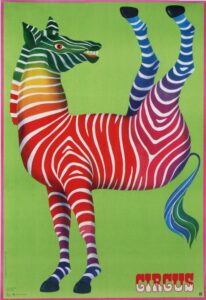

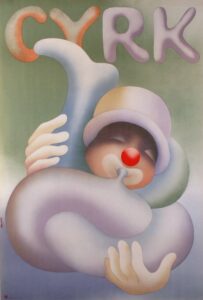

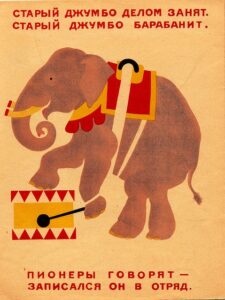

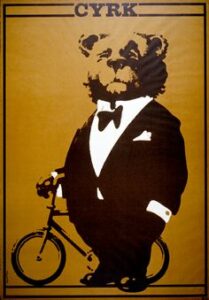

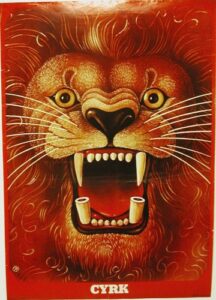

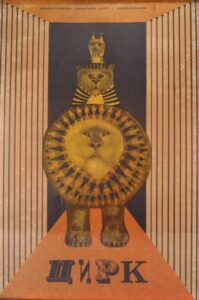

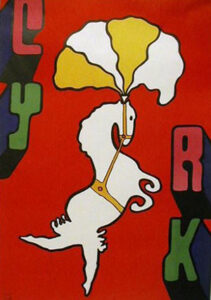

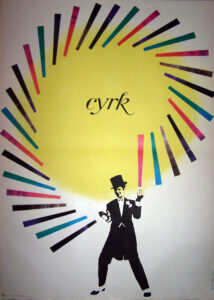

I have always loved circus and fairground decoration/art/imagery and found these beautiful posters on ebay. These are (I believe) 1960’s Russian circus posters. I have included some of my favourite also from Poland. Great for children’s rooms and not too expensive, they come up on ebay from time to time.